Mimaki

Mimaki TXF150-75 DTF Printer with 32" BRSP Falcon Shaker

Mimaki TXF150-75 DTF Printer with 32" BRSP Falcon Shaker

Couldn't load pickup availability

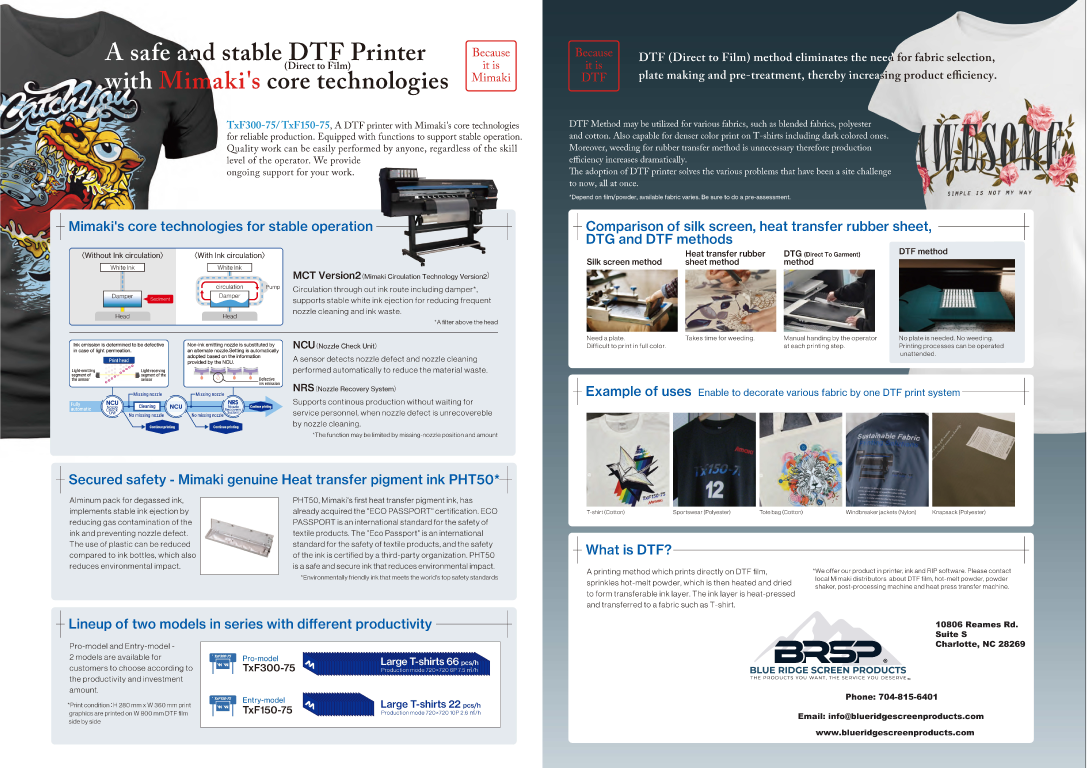

- Eco-friendly cartridge ink with aluminum pack design

- NCU & NRS automatically detect missing nozzles to minimize downtime.

- MCT (Mimaki Circulation Technology), a white ink circulation system for stable printing

32" BRSP Falcon Shaker

All-In-One PLC Control Touch Panel

Easy operation and automatic production.

Integrated Internal Smoke Purifier

Stronger smoke purifying capability, compact design, and more environmentally friendly.

Intelligent Powder Spray System

Process greatly reduces the amount of time the powder needs to be recycled, resulting in decreased labor and increased efficiency.

Two Sided Heater

Heating system uses lamps on top and bottom to regulate temperature gradually. Bottom heater slows down ink drying by gradually increasing temperature, while top heater accelerates powder melting by gradually decreasing temperature to ensure even powder application and curing each time.

Intelligent Heater Control

Saves 30% power by automatically turning off heater when reaches desired temperature and prevents film overheating if machine pauses or stops operation.

Specifications:

| Maximum film width | 32” in. | |

|---|---|---|

| Pre-heat Temperature | 0-100oC (0-212oF) | |

| Heater Temperature | 0-150oC (0-302oF) | |

| Exhaust | 350 m3 / per hour (6 m3/min.) | |

| Power specification | Single-phase (220V AC ± 5%, 50/60 Hz, 30Amps) | |

| Power consumption | Working Mode: 5000W (Energy Saving: 2KW in 1 hour) | |

| Environment | Temperature: 18-30℃ (65-86 ºF), Humidity: 30-70% RH | |

| Machine size | 76” x 45” x 45” in. (LxWxH) | |

| Machine weight | 750 lbs. | |

Highlights of the Mimaki and Blue Ridge.

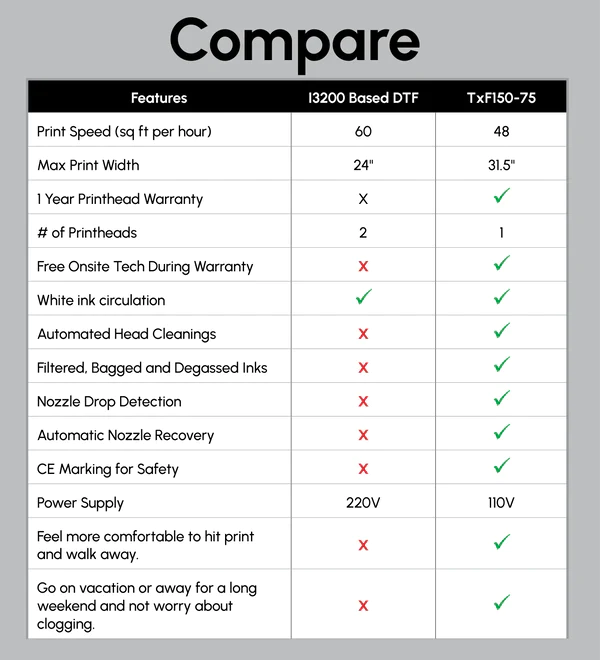

- One-Year Complete Warranty, including printheads and onsite support if something goes wrong

- Reliable ink system design to reduce clogging and downtime

- Better ink consistency than other brands and models

- Self-Cleaning

- Groundbreaking ink technology circulating through the damper

- Nozzle Detection

- 31.5” Printing Width

- Onsite certified Mimaki technician setup and training

- World-class support from Blue Ridge Screen Products and Mimaki USA

Included with the Mimaki TxF150-75 Printer/Dryer package:

- Two day onsite setup and training

- Inks, powder, and film to get started

- 1-Year Complete Coverage Warranty* - Includes printheads and onsite support if needed. *Head strikes are not covered under warranty. See Mimaki Warranty for details

- Dryer - 1-Year warranty. Tech travel expenses are not included.

-

Need Assistance with Mimaki Products?

Our team is committed to your success and satisfaction. We are passionate about helping the printing community through knowledge, education, and service. Need additional information on our products, contact us today and we will be happy to assist!